- Home

- portfolio

- Turnkey Plants

- ZERO DISCHARGE SYSTEM

ZERO DISCHARGE SYSTEM

Turnkey Plant

- Aloe Vera Powder Plant

- Coconut Milk Powder Plant

- Egg Powder Plant

- Fish Protein Hydrolysate Powder Plant

- Fruit Powder Plant

- Ice-Cream Mix Powder Plant

- Lactose Powder Plant

- Malt Powder Plant

- Microcrystalline Cellulose Powder Plant

- Non-Dairy Creamer Powder Plant

- Pectin Powder Plant

- Soy Milk Powder Plant

- Sugarcane Juice Powder Plant

- Tamarind Extract Powder Plant

- Zinc Sulphate Powder Plant

- Zero Liquid Discharge System

ZERO DISCHARGE SYSTEM

Zero Liquid discharge system can be of various configuration. Which Includes, Basic Anaerobic + Aerobic treatment of waste water followed by Belt filter for sludge and Paddle Dryer for Sludge drying.

In zero Discharge System, the scheme given is Stripper + Multiple effect evaporator + ATFD.

STRIPPER COLUMN:

Stripper column includes a stripper column, reboiler where the steam is given, condenser from where VOC distillate is removed.

In this scheme, feed is fed to stripper column to strip off volatile organic contents with two aims in mind:

The volatile contents if not stripped off will vaporize in MEE but do not get easily condensed in condenser of MEE. As a result, the volatiles will over load the vacuum pump and therefore the operating temperatures in MEE will just shoot up. MEE performance will severely get affected.

Second reason for putting a stripper is; whatever volatiles condense in MEE, will render the MEE condensate with some COD in it. The more we can stripper the feed lesser and lesser will be the COD in MEE condensate.

The streams coming out from stripper column are stripped product from bottom and volatile distillate from top. The VOC condensate is to be incinerated. The product from stripper column is fed to evaporator.

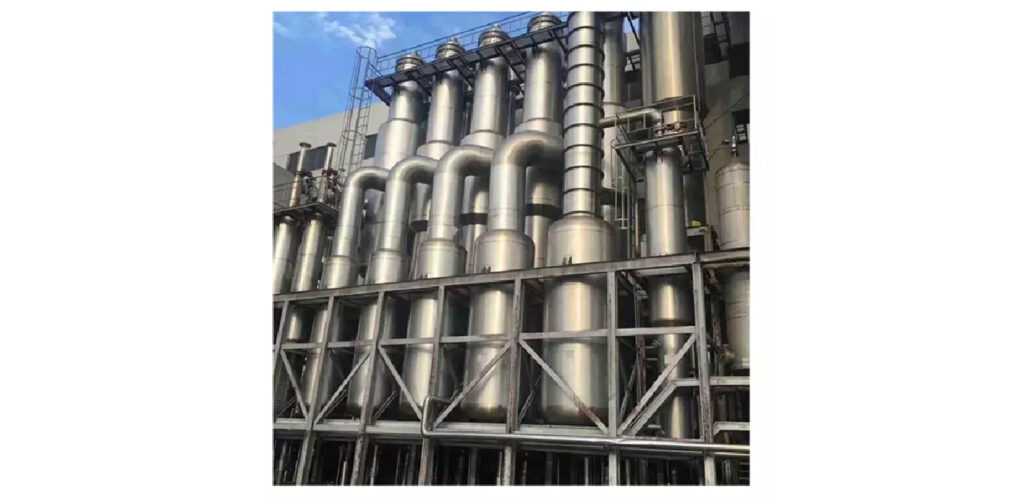

MULTIPLE EFFECT EVAPORATOR:

MEE is used to concentrate the feed i.e. reduce the volume of the effluent.

It includes heat exchangers (calandria, preheaters, and condenser).

Streams coming out from evaporator are:

Evaporated Condensate and concentrated product

The evaporated condensate can be recycled as raw water.

Concentrated product is fed to ATFD to further reduce the effluent volume.

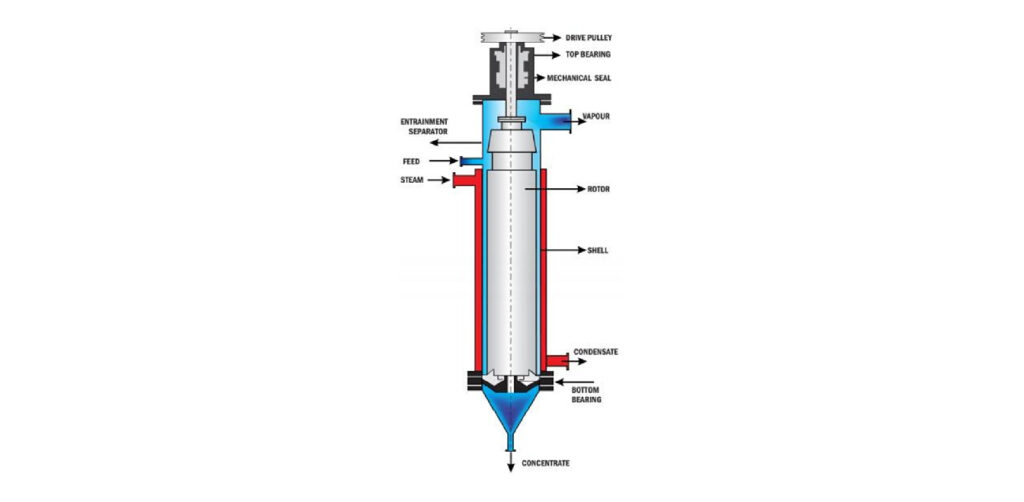

AGITATED THIN FILM DRYER (ATFD):

ATFD is a specially designed film type dryer for handling highly concentrated solutions and the aim is to achieve powder. It includes, dryer which is a jacketed vessel where the steam is given and a condenser where the evaporated vapors are condensed.

Streams coming out from ATFD are:

Evaporated Condensate and final product which is in powder form.

The evaporated condensate can be recycled as raw water.

The solids waste generated is to be incinerated if it is combustible or it is to be sent for secured land filling.