- Home

- portfolio

- Turnkey Plants

- NON DAIRY CREAMER POWDER PLANT

NON DAIRY CREAMER POWDER PLANT

Turnkey Plant

- Aloe Vera Powder Plant

- Coconut Milk Powder Plant

- Egg Powder Plant

- Fish Protein Hydrolysate Powder Plant

- Fruit Powder Plant

- Ice-Cream Mix Powder Plant

- Lactose Powder Plant

- Malt Powder Plant

- Microcrystalline Cellulose Powder Plant

- Non-Dairy Creamer Powder Plant

- Pectin Powder Plant

- Soy Milk Powder Plant

- Sugarcane Juice Powder Plant

- Tamarind Extract Powder Plant

- Zinc Sulphate Powder Plant

- Zero Liquid Discharge System

NON DAIRY CREAMER POWDER PLANT

Non-Dairy Creamers are widely used as whitening agents, also as the texture/mouthfeel modifier with hot and cold beverages, e.g., coffee, cocoa, tea, etc. They are commonly used in place of milk and/or dairy cream. Creamers may come in a variety of different flavours and provide a whitening effect, mouthfeel, body, and a smoother texture.

ADVANTAGES AND USAGE OF ICE CREAM MIX POWDER

- Non-Dairy Creamer can be manufactured with wide range of fats from different fat source formulations to meet customer’s diverse requirements.

- flavoured & non-flavoured Non-Dairy Creamer variants can be manufactured.

- Non-Dairy Creamers are specially developed on basis of specific applications such as coffee, tea, smoothies, shakes, nutritional beverages, Infant food formulas, bakery products, fat-filled milk powders, seasoning, convenience foods, frozen desserts and many more.

- Long shelf life

- Simple to use.

- Easy to store and transport no special requirement of refrigeration.

- Reduced volume so reduced cost of shipping and transportation.

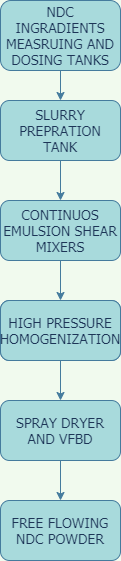

PROCESS DESCRIPTION:

1 FEED PREPARATION – INGREDIENTS MIX:

This is a simple process which involves mixing of various ingredients like powder fat, which can be either obtained from non-dairy product sources, i.e. cream or from other sources, such as palm kernel oil/sunflower oil/peanut oil, along with corn syrup, solid sugar, protein, emulsifier, stabilizer, and flavourings, in a proper proportion by auto weighing system. The large tanks with specially designed efficiently mixing and blending agitator arrangement are provided to mix the ingredients. The tanks are also provided with the heating arrangement so as to maintain proper temperature for producing right slurry formulation depending on the ingredients.

2. HOMOGENIZATION

The mix is homogenized, usually by passing through a high-pressure homogenizer. The mix is also homogenized, which forms the fat emulsion by breaking down or reducing the size of the fat globules. Homogenization provides the following functions in NDC manufacture:

- Reduces size of fat globules

- Increases surface area

- Forms membrane

By helping to form the fat structure, it also has the following indirect effects:

- gives a greater apparent richness and palatability

- better air stability

- increases resistance to melting

3. SPRAY DRYING:

The feed is then dried to powder form in a Spray Dryer. The feed is atomized to fine droplets in a large spray chamber by using series of high-pressure nozzles. These atomized particles come in contact with hot air and water in it gets evaporated. The dried product is discharged at the bottom of chamber. The dried product entrained with the exhaust air is separated in a high efficiency Cyclone Separator. The exhaust air is further passed through a secondary Cyclone Separator and or Wet Ventury Scrubber for recovering the fines not separated in primary cyclone. Clean air is then vented to the atmosphere. The entire operation of the plant is monitored and controlled through a locally mounted control panel or through PLC as per customer choice.

FEATURES:

- Low temperature drying which maintains the qualities of the ingredients in the homogenized Powder.

- cGMP construction of equipment to maintain high hygiene level.

- Fully automatic, compact and energy efficient system to ensure smooth and ease of operation.

- Plant foot print is planned as per availability of land from customer.

- Complete sanitary design with CIP system